- amtec

- YRT English

- Service

- amtec Products

- amtec Assembly Tools

AMTEC Assembly Tools

Hydraulic Tensioning

In the case of safety-related components, e.g. in nuclear power plants, we rely on the hydraulic clamping method, since friction effects are of secondary effect and there are practically no torsional stresses in the bolts.

All bolts in a joint can be tightened at the same time, eliminating the need for a complicated tightening sequence. In addition, the elements of the connection - especially the sealing elements - are loaded beyond their subsequent preload. Setting and relaxation processes are thus accelerated and have subsided at the end of the clamping process.

Monitoring of the Bolt Stress

In order to control the level of the resulting bolt stresses and to narrow the scatter band of the stress, an explicit measurement of the bolt stress may be necessary. Therefore, in addition to the hydraulic clamping devices, we have developed various systems that allow a complete control of the clamping process.

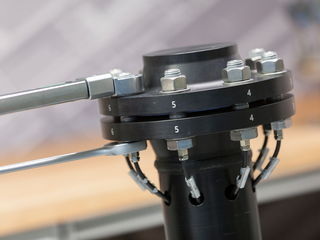

Under the product name TEMESfl.ctrl we manufacture hydraulic tensioners for the assembly of flange connections, which can be used either as individual clamping cylinders or as a complete system.

In the TEMESokto.ms system, the TEMESfl.ctrl tensioners are equipped with specially developed elongation measuring elements - the "OKTO" sensors - which are placed directly on top of the tension nuts. They measure the elongation of bolts with an inner pin during the entire tightening process.

All stages of the tensioning process are visible on the screen of a connected notebook/tablet. This allows individual bolts to be adjusted in a controlled manner and the resulting preload can be achieved with high precision.

At the end of the tensioning process, the quality of the assembly can be documented.

Flange Assembly Training Tools

For the training of fitters amtec developed several practice tools for the measurement and visualization of bolt forces during the tightening process under real mounting conditions.

- Flange Assembly Practice Tool TEMES fl.apt

- Training device for the measurement of torque and bolt forces TEMES bolt.ctrl

- Device for the Measurement of torque wrenches TEMES tq.ctrl

- Assessment Equipment TEMES fl.fat

The amtec training flange is used for the measurement and visualization of bolt forces during the tightening process under real mounting conditions. The pair of flanges (DN100/PN40) is assembled with eight screws (M20), all of which serve as force sensors. The user-friendly amtec software, developed especially for demonstration purposes, shows the bolt forces in various graphics.

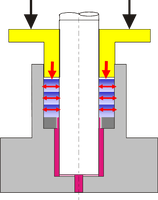

Assembly of Stuffing Box Packings

Assembly is a very important step to achieve tightness and function of stuffing box stem seals.

During assembly, a good seating of the packing has to be reached, first. This is realized by plastic deformation of the packing rings. Existing gaps (between stem and packing / packing and housing / between the rings) have to be filled and internal leakage paths have to be closed. This process is accelerated with increased load.

After this pre-deformation a given assembly stress value (tightening torque) has to be applied. Usually, the packing is compressed axially using a gland and bolts; the main tightening surfaces are between stem and packing / packing and housing. Therefore, regarding tightness a sufficient radial force (better: radial stress) has to be maintained during every state of operation.

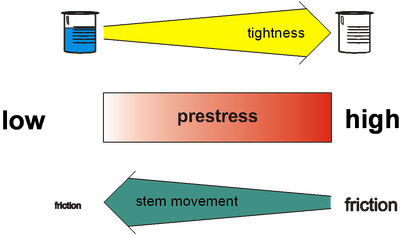

However, the preload of the packing rings also increases the frictional force between the stem and the packing material, which impairs the mobility of the stem. In order to minimize the frictional force and maintain the mobility of the stem, the preload of the packing rings should be as low as possible.

Both requirements, on the one hand the high tightness of the connection, on the other hand the low stem frictional force, represent contradictory demands on the amount of preload of the packing rings during assembly.

In order to obtain a tight and functional fitting, care must be taken during assembly to apply sufficient but not too high pretension.

- hydraulic cylinders,

- tension nuts for different thread sizes,

- adjusting rings for different nut sizes and

- hydraulic hand pump.

For all applications in which documentation of the installation packing stress is required, our system TEMESstb.ctrl with a metrological extension offers the possibility of measuring and recording both the bolt force and the deformation of the packing rings.

Controlled Prestressing of Stuffing Box Packings with

AMTEC hydraulic tensioning.